Precisely fitting valve insulation for fittings and products

Precisely fitting valve insulation for fittings and products

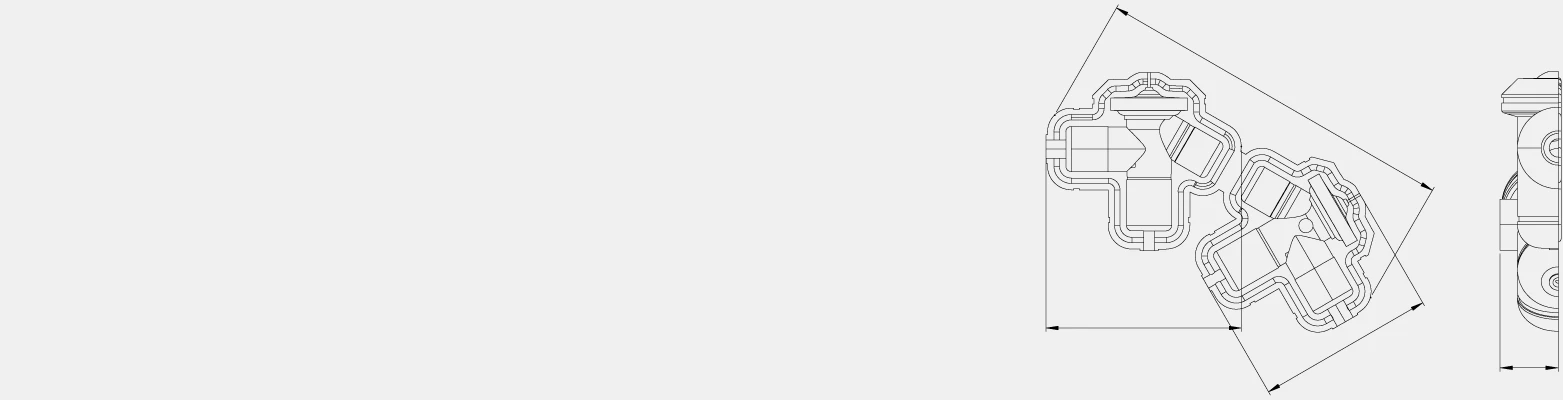

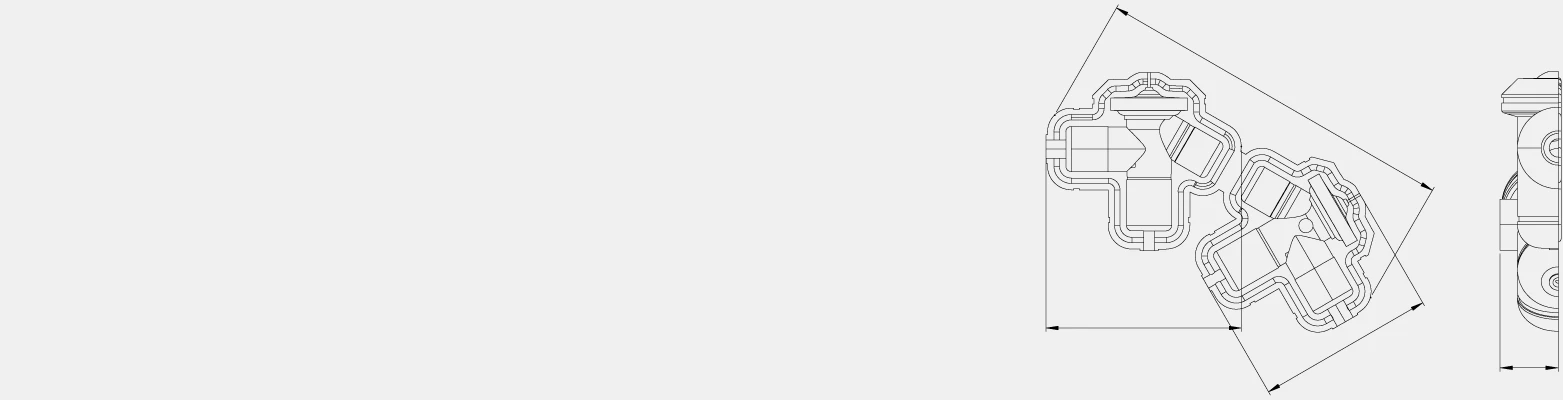

The heart of our insulating shell development beats in the “Product and Process Development” department: This is where 15 years of development experience in the field of valve insulation meets state-of-the-art CAD systems with experienced designers and our in-house toolmaking department.

At ISOWA, we develop a customized product solution for you that is tailored to your specific requirements and wishes. We don't just produce an “insulating shell” for you - we want to find a holistic insulation solution.

In order to optimize your production chain and enable smooth installation, we also tailor all logistical aspects to your needs. This can be done by telephone or video call, but also in person with our technicians on site.

Successful collaboration with ISOWA begins with a prototype. In order for our product to support your success in the best possible way, it is important that we know all the relevant facts and your exact requirements. Based on your requirements and our specialist knowledge, a detailed solution proposal for your individual valve insulation is created.

Cross-linked polyethylene (PE) foam

Individual insulation thicknesses according to requirements

Scratch-resistant surface thanks to stable PE grid

Water vapor diffusion factor μ ≥ 5000

Fire behavior class E

Thermal conductivity < 0.034 / 0.040 W/mK at 10°C / 40°C

Can be used in the temperature range from -80°C to +100°C

Step 1

Definition of your requirements (temperature range, diffusion tightness)

Step 2

Determination of the function (heat, cold, or both?)

Step 3

Determination of continuous & extreme load

Step 4

Optimization in terms of shape & dimensions (tongue & groove, locking technology)

Step 5

Definition of the design (own design, branding / logo)

Step 6

Proposal for a better solution

INQUIRY

INDIVIDUAL OEM SOLUTION